Product description:

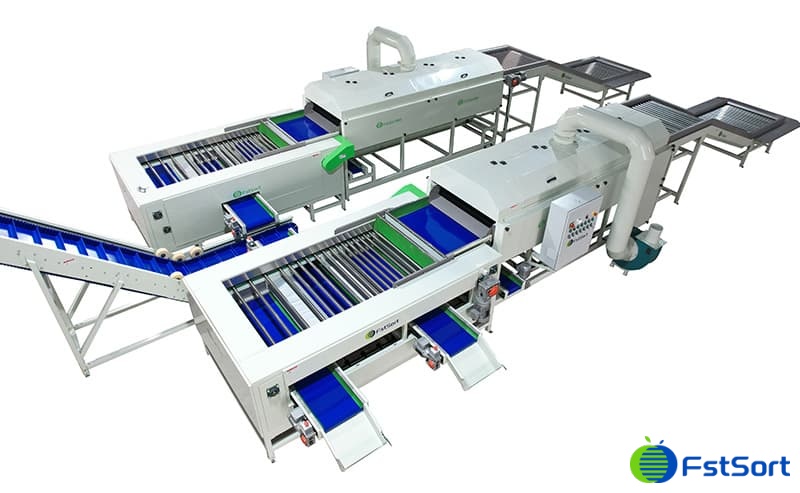

This Fstsort potato grader is designed to replace the traditional screen sizer, and provides an perfect combination of accuracy, capacity, and price. PVC rollers rotate the potatoes for workers to do quality inspection, and finally grade on three to six sizes. Either the bag closing device weighing system can help you do packing directly.

Features:

1. Roller inspection tables - roller conveyor provide an efficient and affordable way to keep your product constantly rotating when manual inspection is required.

2. Variable speed- Variable-speed operation can be achieved either by mechanical or electrical adjustment.

3. Outfeed Conveyors - Gentle and durable belts can carry your product to either side of the Sizer. End with a Bag closing device or slope exit as needed.

4. Easy to use, simple maintenance, Wheels on the legs for easy movability.

5. Customize -

1) Material: we provide stainless steel on product contacting points or fully stainless steel.

2)Processing lines can be provided with big feeding hopper, roller inspection table, dry cleaning, wet cleaning, weighing and packing system.

6.Application: Suitable for a wide range of vegetables including sweet potatoes, carrots, onions, brussel sprouts, celeriac, beets, capsicums, parsnips, swedes and bulbs.

Specification:

| Model | Capacity | Grades | Dimension(mm) | Power | Voltage |

| FIPG-8000 | 8t/h | 3-6 | 9260*1500*1220 | 2.6KW | 220V/380V |

| FIPC-5000 | 5t/h | 3-6 | 9010*1820*1700 | 2.6KW | 380V |

FIPG-8000 (large capacity grader)

FIPC-5000 ( 20 brushes+size grader)

Gemini potato washing and grading machine customized for Iranian customer(Elevator + Dry cleaner + Adjustable roller grader)

Potato washing drying grading processing line

Potato Receiving Hopper

Product description:

A potato receiving hopper is a piece of machinery, usually located at the entrance of a processing line, that receives and temporarily stores potatoes before they are sorted and processed.

How it works: A potato receiving hopper is usually a large, open container with a sloped bottom that allows potatoes to be unloaded from a truck or trailer and transferred into the hopper. The hopper may be equipped with a conveyor or other loading device to assist in transferring the potatoes into the hopper. Once the potatoes are in the hopper, they are stored until they are ready to be sorted and processed.

Advantages:

Increased efficiency: A potato receiving hopper allows potatoes to be quickly and easily unloaded from trucks or other vehicles, which can help to increase the overall efficiency of the unloading process.

Efficient: Potato receiving hoppers are designed to be efficient and able to unload potatoes in a timely manner, helping to minimize delays and keep operations running smoothly.

Preliminary cleaning: The receiving hopper is equipped with cleaning rollers and other devices. After the potatoes enter the hopper, the dirt and impurities on the surface of the potatoes can be initially cleaned by the rolling of the cleaning rollers, etc., so as to reduce the soil content on the surface of the potatoes and reduce the burden of subsequent cleaning processes.

Specification:

| Size(mm) | 4200*1950*1450 |

| Handling capacity(t/h) | 15 t/h |

Inlet height | 830-1300mm |

Capacity | Approximately 3 cubic meters |

Outlet height | 750-1050mm |

Power | 1.75 kw |

Voltage | 220 v |